Vertical Roller Mill Cement Cost

.jpg)

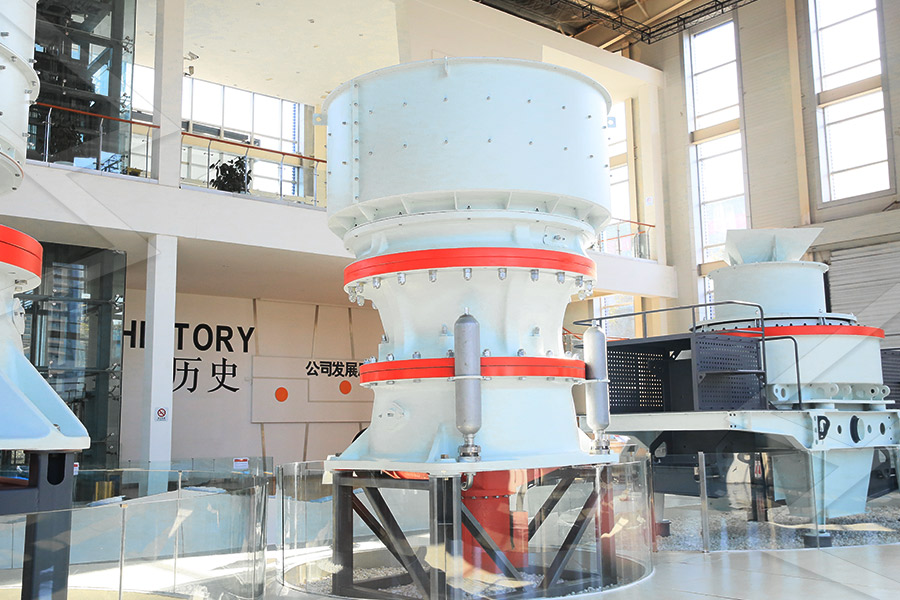

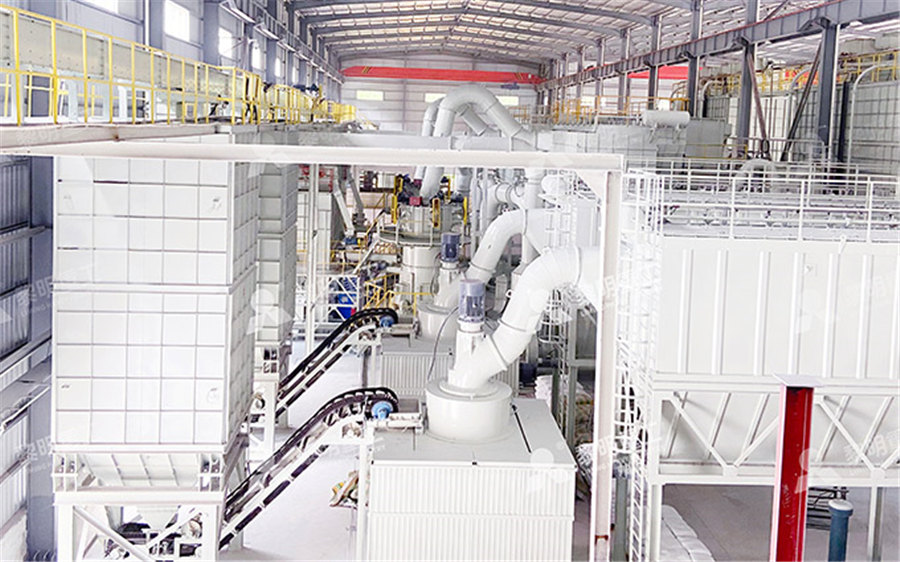

Vertical roller mill vs ball mill for cement grinding:

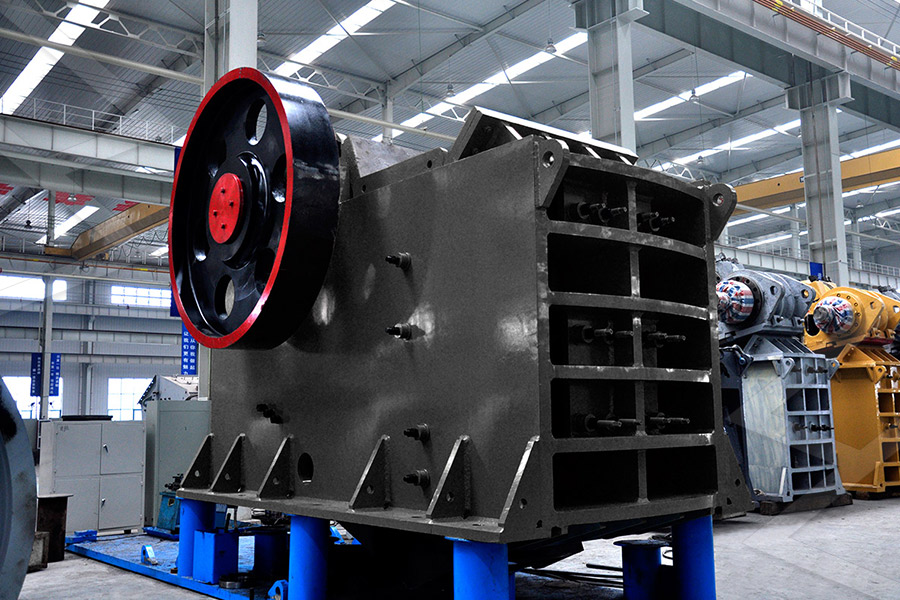

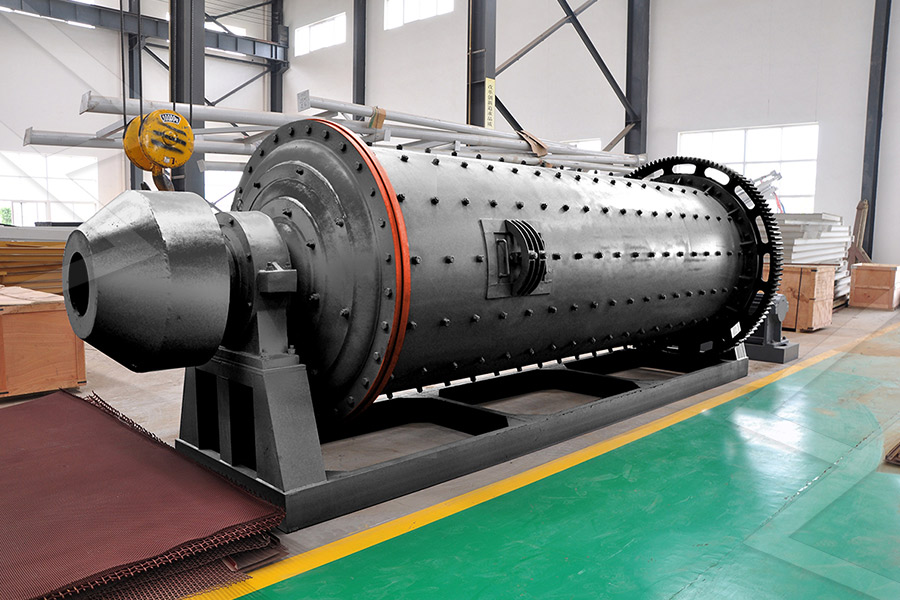

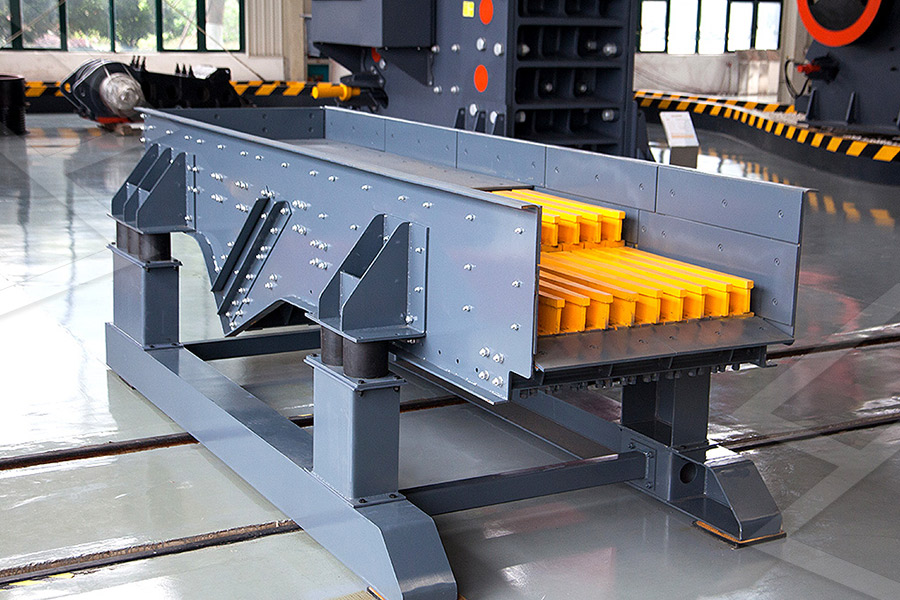

The choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant VRMs offer As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise Vertical roller mills FLSmidth CementSelecting a single large vertical roller mill size gives you lower total cost of ownership per tonne of cement produced Common parts increase equipment availability, lower maintenance and parts inventory costs and OK™ Raw and Cement Mill FLSmidth Cement2016年1月4日 The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills These days, the vertical roller mills have been widely Vertical roller mill for raw Application p rocess materials

.jpg)

VERTICAL ROLLER MILLS A holistic VRM approach

2022年4月4日 The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and 2004年4月30日 As the Vertical Roller Mill (VRM) becomes more widely accepted for new cement grinding systems differences in installed costs between a VRM and a ball mill systInstalled cost comparison for cement grinding systems2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller Review on vertical roller mill in cement industry its 2024年5月10日 Baichy Mill is a globally successful vertical roller mill solution for grinding raw materials, cement, and slag Its cuttingedge design features consistently deliver the Vertical roller mill for cement and slag grinding

.jpg)

SikaGrind® for vertical roller mills

1 天前 CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS 5 RECOMMENDATION Cement qualities for nonstructural applications with low specific surface (low Blaine) are This article will explore the application of vertical roller mills in the cement industry, including their benefits, efficiency, and ecofriendly features Understanding Vertical Roller Mill Technology Vertical roller mill (VRM) Application of Vertical Roller Mill in Cement Vertical roller mills can be transported in parts and constructed onsite, avoiding difficult logistical issues and associated costs The fineness of product cement can be adjusted easily with the vertical roller mill The Cement Mill for Sale Buy Cement Ball Mill2020年11月5日 Vertical roller mill Vertical roller mill, also called cement vertical mill, it grinds raw materials by the movement between grinding roller, millstone and grinding device In general the grinding efficiency of 3 Necessary Cement Milling Comparison Ball

(PDF) Performance Evaluation of Vertical Roller Mill in Cement

2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research 2024年5月23日 The clinker vertical roller mill (VRM) has become an integral part of the cement manufacturing process Over the past few decades, this equipment has undergone significant advancements, reflectingThe Evolution of Clinker Vertical Roller Mills: From Inception 2024年9月2日 Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our mills The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesche‘s pioneering engineering knowhowCement Industry LoescheThe most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg, and the fuel cost accounts for Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

.jpg)

Vertical roller mill for raw Application p rocess materials

2016年1月4日 Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including At the beginning stage when vertical roller mill was adopted to cement manufacturing, mill gas circulation fan and dust collection fan are required and theirThe MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unitCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsVertical Roller Mills Cement Limestone Powder Grinding Mill Vertical Roller Mill in Cement Industry Price US$ 3650036900 / Piece 1 Piece (MOQ) Zhengzhou General Mining Machinery Co, Ltd View larger video image Contact Now Add to China Vertical Roller Mill, Vertical Roller Mill Wholesale Find your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth DorrOliver Eimco, SBM Shibang Group, CHAENG, ) on DirectIndustry, the industry specialist for your professional purchases Vertical roller mill, Vertical roller grinding mill

Vertical Cement Mill Magotteaux

Understanding Our Proprietary Vertical Cement Mill Technology Magotteaux’s proprietary vertical cement mill technology has been developed through decades of innovation and expertise in grinding 2021年10月14日 The vertical roller mill is suitable for grinding quartz, feldspar, calcite, cement clinker, activated carbon, dolomite, granite and other nonflammable burst materials whose hardness are below 93 The innovative design ensures that it grinds the material directly on the disc, with low energy consumption The roller is not contact with the disc Vertical Roller Mill Indian Cement Review1 天前 CEMENT 4 SikaGrind® FOR VERTICAL ROLLER MILLS Pilot Mill (Picture: Loesche GmbH, Germany) The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy saving ́ Higher fineness, faster strength development ́ Reduced vibration, SikaGrind® for vertical roller millsThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The Vertical Roller Mill Operation in Cement Plant

Vertical Roller Mill in Cement Plant ball mills supplier

Energy efficiency: VRMs require less energy to operate compared to ball mills, resulting in lower electricity costs and reduced carbon emissions Overall, the use of vertical roller mills in cement plants represents a significant step towards sustainable and efficient cement production By adopting this technology, cement plants can reduce Drive Systems for Vertical Roller Mills Reduction of investment costs is one of the most important driving factors for this trend Because of simple scalability and low energy consumption, the vertical roller mill is a key part for single mill cement lines Market trends in vertical mills for the cement industry ZKG International 0102 Drive Systems for Vertical Roller Mills INFINITY FOR CEMENT 2023年7月4日 A cement vertical roller mill (VRM) is a type of grinding equipment commonly used in cement plants for raw material grinding and cement grinding It is an energyefficient alternative to traditional ball mills, as it utilizes rollers to grind and crush the materials between a rotating grinding table and a set of rollers mounted on a vertical axisVertical Roller Mill in Cement Manufacturing Plant2022年5月9日 The raw materials were mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The raw vertical roller mill has four rollers, 3000 KW main drive, 48 m table diameter, 2 Modeling of energy consumption factors for an industrial cement

Review on vertical roller mill in cement industry its

2021年1月1日 A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true Vertical roller mill The feed is ground by pressure and friction between the horizontal rotating table and 4 to 6 grinding rollers in the VRMVertical roller mills can be transported in parts and constructed onsite, avoiding difficult logistical issues and associated costs The fineness of product cement can be adjusted easily with the vertical roller mill The Vertical Roller Mill for Sale AGICO Cement Plant2021年1月29日 In recent years vertical roller mill (VRM) has proved to be a popular choice for finished cement grinding due to low power consumption but it is also very sensitive to vibrations and can Increase productivity of vertical roller mill using The cement mill can be used as a raw mill or cement grinding mill, AGICO Cement provides vertical cement mill, cement ball mill and other highquality cement grinding machines for you! Generally, the cement mill can be Cement Mill Cement Ball Mill Vertical Cement

China Cement Vertical Mill, Cement Vertical Mill Wholesale

The cost of a Cement Vertical Mill can vary widely depending on its size, capabilities, and complexity Most of the price of Cement Vertical Mill ranges from US $ 2000 to $ per Piece It's important to research and compare different models and features to find the best Cement Vertical Mill for your needs and budget2017年8月11日 large vertical roller mills for grinding cement raw material Redundancy und interchangeability – große VertikalRollenmühlen für die Rohmehlerzeugung chiefly on cost grounds, the trend will continue towards large production units with kiln capacities of up to 10 000 t/d Investigations have shown that upRedundancy and interchangeability – large vertical roller Understanding Vertical Roller Mills in Cement Industry Vertical roller mills (VRMs) are pivotal to the cement production process As a sophisticated piece of industrial machinery, a vertical roller mill in cement industry price reflects its necessity and functionality in grinding raw materials into fine powders These mills are distinguished by their vertical orientation Vertical roller mill in cement industry price2019年10月18日 Vertical cement mill and related vertical mill system The vertical cement mill system has features of high output and less energy consumption, so it is widely applied to the cement grinding The vertical cement mill has some similarities with cement roller press, both of them use the material bed to do the full crush But the contact surface How To Select Cement Mill? Cement Ball Mill, Vertical Cement Mill

Roller Mill SpringerLink

2023年7月4日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power industry, the preparation of nonmetallic ore ultrafine powder, manganese ore fine grinding, and other fields It was successfully designed in 1984, the first high pressure roller 2021年1月6日 The acceptable feed size of a ball mill is 2530 mm, independent of mill size The vertical roller mills can accept feed sizes up to 100150 mm, depending on the mill size [111][112] [113] For Review on vertical roller mill in cement industry its MVR vertical roller mill from Gebr Pfeiffer with patented multiple drive system MultiDrive® for the highest throughput rates and permanent plant availability Highquality wear materials, sophisticated maintenance Cement mills and raw mills for high throughput 2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller mill

Cement mills and raw mills for small to medium throughput

For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice This mill type is by the way the core piece of our modular ready2grind system different wear materials are used on our vertical roller mills Alloy cast iron as 2024年5月10日 Baichy Mill is a globally successful vertical roller mill solution for grinding raw materials, cement, and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and costeffective to operate over your cement plant’s lifetimeVertical roller mill for cement and slag grinding2022年7月26日 energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further arguments for VRMs, unpretentious Grinding Aids add a perfect cost/ benefit ratio Sophisticated cements or certain process limitations, eg a bottleneck Picture: Loesche GmbH, Germany CEMENT SikaGrind® Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeMilling and grinding FLSmidth Cement

.jpg)

Making gains with OKâ„¢ cement mill Indian Cement Review

2021年10月19日 Since 1982, the OK??vertical roller mill (VRM) has provided the cement industry an energyefficient, flexible ??both in terms of size and the ability to handle variable feed materials ??and reliable solution for cement grinding These benefits are ever more relevant today, as cement producers focus on reducing both operating costs and their 2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical Compression crushing is also the main crushing mechanism in the VRM, but there is also shear force between grinding roller Analysis of vertical roller mill performance with changes in 2013年3月13日 TRM series Cement Vertical Roller Mill is the specialized equipment for cement grinding based on TRM series Raw Vertical Roller Mill The initial TRMK4541 Cement Vertical Roller Mill was operated inTRM SERIES CEMENT VERTICAL ROLLER MILL TRM Lower operating costs: Vertical roller mills have lower operating costs than traditional mills due to their lower power consumption, maintenance costs, and overall footprint Higher grinding capacity: Vertical roller mills can handle up to 25% more capacity than traditional mills, making them ideal for large cement plants with high throughput How does vertical roller mill work? ball mills supplier

Application of Vertical Roller Mill in Cement

This article will explore the application of vertical roller mills in the cement industry, including their benefits, efficiency, and ecofriendly features Understanding Vertical Roller Mill Technology Vertical roller mill (VRM) Vertical roller mills can be transported in parts and constructed onsite, avoiding difficult logistical issues and associated costs The fineness of product cement can be adjusted easily with the vertical roller mill The Cement Mill for Sale Buy Cement Ball Mill2020年11月5日 Vertical roller mill Vertical roller mill, also called cement vertical mill, it grinds raw materials by the movement between grinding roller, millstone and grinding device In general the grinding efficiency of 3 Necessary Cement Milling Comparison Ball 2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill in Cement

.jpg)

The Evolution of Clinker Vertical Roller Mills: From Inception

2024年5月23日 The clinker vertical roller mill (VRM) has become an integral part of the cement manufacturing process Over the past few decades, this equipment has undergone significant advancements, reflecting2024年9月2日 Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our mills The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesche‘s pioneering engineering knowhowCement Industry LoescheThe most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg, and the fuel cost accounts for Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill2016年1月4日 Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including At the beginning stage when vertical roller mill was adopted to cement manufacturing, mill gas circulation fan and dust collection fan are required and theirVertical roller mill for raw Application p rocess materials

.jpg)

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unitVertical Roller Mills Cement Limestone Powder Grinding Mill Vertical Roller Mill in Cement Industry Price US$ 3650036900 / Piece 1 Piece (MOQ) Zhengzhou General Mining Machinery Co, Ltd View larger video image Contact Now Add to China Vertical Roller Mill, Vertical Roller Mill Wholesale