Jaw Crusher InurlDXNhay

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

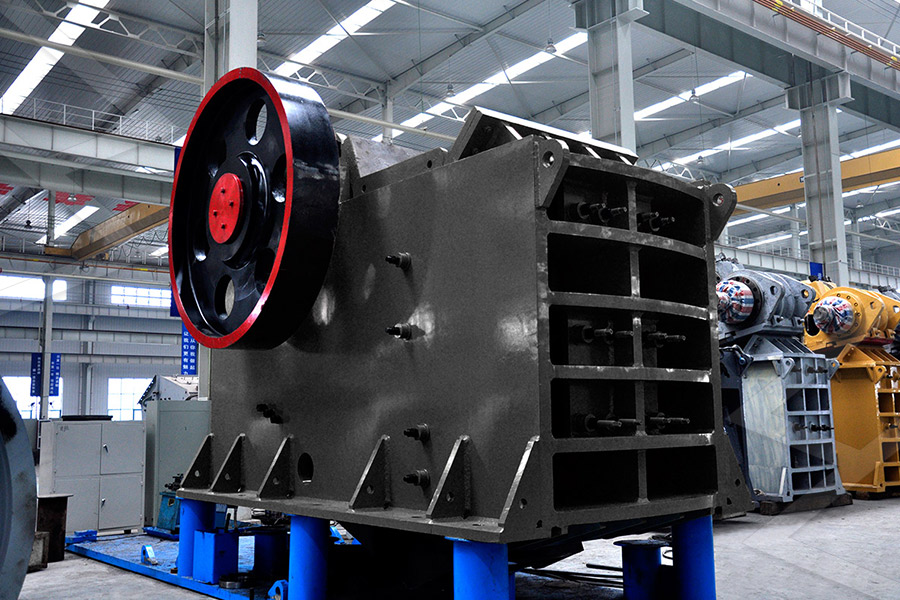

A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but 2024年9月9日 The C5X Jaw Crusher boasts superior motion characteristics and C5X Jaw CrusherSBM Industrial Technology GroupOur company is a professional manufacturer specializing in the research, development and production of complete crushing equipment used for stone crushing, sand making, screening and separation, mainly producing Jaw Crusher Manufacturer, Impact Crusher, Cone Sandvik QJ341 mobile jaw crusher features a 1,200 x 750mm (47 x 29 in) jaw opening, built to tackle the most difficult applications with ease It has been designed to meet the needs of the operator seeking a high Sandvik QJ341 Mobile Jaw Crusher – World

.jpg)

Jaw Crushers Crushing Equipment Minyu

2023年8月7日 With larger feed openings and bigger crushing strokes, the Minyu Jaw Crushers are suitable for crushing big size lumps in large quantity They are especially recommended for primary and concrete Sandvik CJ409 jaw crusher is suitable for a wide range tough applications due to its heavyduty design coupled with its reliabilty and stability CJ409 Features Product data Request a quote Manual (shim) setting CJ409 Jaw crusher SRPThe crushing performance of a jaw crusher depends on the operational sloped angle of the jaws (1) and the ir shape, the speed and the movement behavior of the fourbar linkage During one revolution of the fourbar Retsch : 产品 : 粉碎设备 : 颚式粉碎仪2017年6月30日 Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing During the crushing (PDF) DESIGN AND OPERATIONS CHALLENGES

Industrial Solutions Jaw crushers ThyssenKrupp

2022年11月21日 The singletoggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) with new crushing elements 2) 1,200 rpm possible All data are intended as a guide only The machine capacity depends on the grain dis tribution as well as the characteristics and the2024年4月25日 Size and Capacity: The size and the capacity of jaw crusher have a considerable effect on the price of the crusher A small jaw crusher having a 250x400mm feed opening and a capacity of 520 tons per hour will cost less than a large jaw crusher with a 1,200×1,500mm feed opening and a capacity of 400800 tons per hourJaw Crusher Price Guide: Everything Buyers Need JXSCJaw Crusher; Description Minex MJC series of single toggle jaw crushers are mainly used for heavyduty continuous applications as primary crushers in aggregates production, mining operations and recycling applications This series includes models of various sizes that are designed to deliver maximum productivity at the lowest operating costsJaw Crusher Minex Solutions3 天之前 A jaw crusher with a wider and shallower jaw can be referred to as a granulator They are also commonly used for secondary and tertiary crushing as they can produce a relatively smaller material size while maintaining an impressive output Model of machine Feed Opening In (MM) recommended Max feed sizeJaw Crushers Sanland Equipment

What Are Jaw Crushers and How Do They Work? Oreflow

The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down4 天之前 Jaw Crushers Designed to crush ROM feed material for demanding quarrying, mining, and demolition purposes With their unique Elliptical motion of the swing jaw Crushers, ensure highly efficient production rates at any settingJaw Crushers Manufacturer in India Puzzolana2024年8月6日 Blake Jaw Crusher: This type of jaw crusher has a fixed feed area and a variable discharge area It is used to crush materials with compressive strength less than 320 MPa Universal Jaw Crusher: This type of jaw crusher is versatile and can handle a wide range of materials It has a fixed jaw plate and a movable jaw plate that is hinged at the Jaw Crusher for Sale Compare Prices SuppliersFor example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimensionJaw Crusher Explained saVRee

Jaw Crusher Eriez

Jaw Crusher 100 x 150 L07000 100 x 150 (4" x 6") Jaw Crusher with: 22 kW Electrical motor; Starter with overload protection; Cast Iron construction with Mild Steel base frame; Vbelt driven with pulley flywheel guard The PE Jaw Crusher is a primary crushing machine equipped with an electric motor that drives the eccentric shaft through the Vbelt and pulley, resulting in the exciting and dynamic movement of the jaw plate It is designed with a higher processing capacity to meet the growing demands of crushing operations in various industriesPE Jaw Crusher GastehysKeunggulan Jaw Crusher Mengenal jaw crusher begitu penting karena berbagai keunggulan yang ditawarkannya, antara lain: Efisiensi Tinggi : Kemampuannya untuk menghancurkan material keras dengan cepat menjadikan jaw crusher pilihan yang efektif dan efisien untuk banyak aplikasi pengolahan mineralMengenal Jaw Crusher, Alat yang Merevolusi Industri 2022年9月22日 Jaw crusher adalah penghancur pola dasar yang digunakan untuk membongkar batu dan batu; dengan jaw crusher, Anda dapat menghancurkan semua jenis material dengan berbagai ukuran tergantung kebutuhan Anda Rahang bergerak memberikan tekanan Tentang Jaw Crusher Omnia Machinery

.jpg)

Jaw Crushers Mt Baker Mining and Metals

Complete and ready to run including jaw crusher, belts, motor, fullenclosure guards, all integrated on a steel skid; Oversized bearings and castings, robust construction, longwearing cast manganese steel jaw plates; Optional steel stand; Sizes: 6”x 10” through 20” x 30″ jaw opening;6 天之前 But many people don’t know that jaw crushers come in all shapes and sizes, from small tabletop models to massive industrial machines So what exactly is a jaw crusher, and how does it work? What Is A Jaw Crusher, And How Does It Work? A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dustJaw Crusher: What Is It How Does It Work? VYKIN Crushers大量翻译例句关于"jaw crusher" – 英中词典以及8百万条中文译文例句。 梯形磨粉机主要由主机,减速机,浓缩粉,引风机,除尘器,管道装置,集成商和电机组成,磨等全系 列 包括 颚式 破碎机, 斗 式 提升 机,磨减速机,Vibraing给料机,主要框架,鼓风机,粉选矿厂,粉收集系统,管道设备和 jaw crusher 英中 – Linguee词典2023年2月15日 a template of jaw crusher checklist 2Do the lubrication job well The lubrication of the interface between the parts of the jaw crusher is very important It can minimize the friction generated during the operation, make the whole jaw crusher run smoothly, and extend its service lifeThe Most Practical Jaw Crusher Repair and Maintenance Manual

The Mechanics of Crushing: Understanding the Jaw Crusher

2023年10月16日 The jaw crusher must be regularly maintained to avoid breakdowns, as mining companies rely heavily on this machinery to help them process their materials without delays Overall, the jaw crusher is an essential piece of equipment widely used across the mining and construction industries and has proven to be an effective way of breaking The main parts and main technical parameters of a jaw crusher are presented below 1 Feed Chute 2 Drive Flywheel 3 Vbelts 4 Electric motor 5 Motor Stand 6 Settings and Damping Group 7 Hydraulic Cylinder 8 Toggle Plate 9 Swing Jaw 10 Discharge 11 Fixed Jaw Parts G: Gape width,WHAT IS A JAW CRUSHER? MEKA2017年5月1日 In a jaw crusher, the material is crushed between two plates: a static plate and a moving plate Compression is applied by the moving plate, and the material becomes crushed The size reduction obtained by a jaw crusher is form conditioned crushing due to the nature of the machine There are two main types of jaw crushers, single toggle and A fundamental model of an industrialscale jaw crusher2022年2月22日 A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top Jaw Crusher: Range, Working Principle,

Jaw Plates: Everything You Should Know

2023年2月16日 Jaw plates are an essential component of the jaw crusher and play a critical role in crushing the material Selecting the right jaw plates is crucial for optimizing the performance and longevity of the crusher By Czech company DS Holding purchased a Sandvik QJ341 jaw crusher and QE241 scalper to increase their operational capacity Looking to invest in mobile equipment to move around sites to recycle construction materials and process aggregates in quarries, they have been delighted with the products from Sandvik and the service they have received from QJ241 Mobile Jaw Crusher Compact Jaw Crusher SRP5 天之前 Model: VYKIN 25JC Configuration: Jaw crusher Power System: Dieseldirect drive Engine: Yanmar tier 4 certified EPA diesel engine (25HP 182kW) Fuel Consumption: 1 – 13 gal/hr, 211 gal capacity Electrical Control: Yes, wireless remote standard Hydraulic Control: Yes, tracks (rubber) Capacity: 1525 TPH (15 TPH at tightest output setting of VYKIN 25JC Mobile Small Tracked Jaw Crusher VYKIN The core of Nordberg® C Series™ jaw crusher is a pinned and bolted, nonwelded frame construction that provides excellent fatigue strength All the frame components are casted using an alloy developed inhouse especially for jaw crushers In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that Nordberg® C Series™ jaw crushers Metso

Retsch Jaw Crushers

5 天之前 The Jaw Crusher BB 400 is used for the rapid, effective crushing and precrushing of mediumhard, hard, brittle and tough materials Its variety of materials offered, including heavymetal free steel, its efficiency and safety makes it ideal for sample preparation in laboratories and industrial plants2024年2月22日 If you think a jaw crusher could be the right tool for the job, contact Boom and Bucket to see our wide array of used work vehicles at affordable prices Visit Boom Bucket to buy and sell your machinery Recent Equipment Browse all equipment 2021 John Deere 9520R 1350 hours $489,200 2022 John Deere 5075E 139 hoursIntro to Aggregate Equipment: The Jaw Crusher2 天之前 A fixed jaw, mounted in a Vshaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on the feed material by pushing it against the stationary plate The space at the bottom of the “V”aligned jaw plates is the output gap that dictates the size of the crushed product from the jaw crusherHow Does a Jaw Crusher Work Kemper Equipment2023年2月21日 The hydraulic jaw crusher is ideal for crushing hard and abrasive materials, and it is commonly used in mining, metallurgy, building materials, and chemical industries One of the advantages of a hydraulic jaw crusher is its ability to adjust the discharge opening easily, allowing for a wider range of output sizes The Ultimate Guide to Jaw Crushing Machines: Types

.jpg)

RM J110X Mobile Jaw Crusher RUBBLE MASTER

Jaw crusher walkaround Join Geoffrey Faber on a tour around the RM J110X mobile jaw crusher RM J110X Specs Capacity: 450 tph 496 TPH: Inlet opening: 1,100 x 700 mm 44" x 28" Crusher unit: Single toggle jaw 2024年7月3日 PE/PEX jaw crusher series is usually called as Jaw Crusher and is a crushing appliance that was produced relatively early and it is generally regarded as the primary breaker and is applied to various What is a PE Jaw Crusher? Jaw CrusherThe "deepcavity jaw crusher" produced by our company has the characteristics of high crushing efficiency and large crushing ratio The "aggregate shaping and impact crusher" is a kind of impact crusher that Jaw Crusher Manufacturer, Impact Crusher, Cone K750 JAW CRUSHER:HOOKLIFT JAW CRUSHER The K750 combines superior crushing performance with the ability to transport with a standard hook lift truck From unloading to operating in less than 5 minutes, the K750 jaw harnesses the power of the onboard Diesel electric generator to crush 0400mm rock, concrete and brick at typically 50100tph Jaw Crushers — Nordmann

.jpg)

Jaw Crushers Parker Plant

3 天之前 Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations The two main types of jaw crusher produced by Parker are both single toggle designs with the upthrust toggle RockSizer / StoneSizer model and downthrust toggle RockSledger model6 天之前 The VYKIN 50JC is a compact midsized mobile tracked jaw crusher and can be used as an excellent concrete crusher It is best for crushing all types of material, such as crushing concrete, asphalt, rock, stone, limestone, pavers and more With a wide jaw inlet opening of 2675” x 17” and a production capacity of up to 50 tons per hour, the VYKIN VYKIN 50JC Mobile MidSized Tracked Jaw Crusher VYKIN 5 天之前 The Powerscreen Premiertrak 420E Jaw Crusher is a midrange crusher used in recycling, quarrying, and mining applications The crusher features a 1070mm x 760mm (42’’ x 30’’) single toggle jaw chamber As part Learn More about Premiertrak 420EJaw Crusher Premiertrak 400X R400X PowerscreenMechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly used crushers due to their ability to crush all kinds of materials of any hardness, as well as their lowcost operation and easy Jaw Crushers AGGRETEK Jaw Crushers for aggregate

.jpg)

Jaw Crushers Molson Finlay

2024年9月3日 The Full Jaw Crusher Range This complete range of tracked jaw crushers offer high performance, robustness and maximum efficiency These machines, otherwise known as mobile crushers, incorporate and combine a heavy duty variable speed VGF and integrated prescreen to give optimum performance in mining, demolition, quarrying and 2024年9月11日 Available in a variety of sizes and configurations, the HydraJaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver highcapacity crushing and reliable performance for increased operational productivity and profitabilityJaw Crushers AstecThe crushing performance of a jaw crusher depends on the operational sloped angle of the jaws (1) and the ir shape, the speed and the movement behavior of the fourbar linkage During one revolution of the fourbar Retsch : 产品 : 粉碎设备 : 颚式粉碎仪2017年6月30日 Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing During the crushing (PDF) DESIGN AND OPERATIONS CHALLENGES

Industrial Solutions Jaw crushers ThyssenKrupp

2022年11月21日 The singletoggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) with new crushing elements 2) 1,200 rpm possible All data are intended as a guide only The machine capacity depends on the grain dis tribution as well as the characteristics and the2024年4月25日 Size and Capacity: The size and the capacity of jaw crusher have a considerable effect on the price of the crusher A small jaw crusher having a 250x400mm feed opening and a capacity of 520 tons per hour will cost less than a large jaw crusher with a 1,200×1,500mm feed opening and a capacity of 400800 tons per hourJaw Crusher Price Guide: Everything Buyers Need JXSCJaw Crusher; Description Minex MJC series of single toggle jaw crushers are mainly used for heavyduty continuous applications as primary crushers in aggregates production, mining operations and recycling applications This series includes models of various sizes that are designed to deliver maximum productivity at the lowest operating costsJaw Crusher Minex Solutions3 天之前 A jaw crusher with a wider and shallower jaw can be referred to as a granulator They are also commonly used for secondary and tertiary crushing as they can produce a relatively smaller material size while maintaining an impressive output Model of machine Feed Opening In (MM) recommended Max feed sizeJaw Crushers Sanland Equipment

What Are Jaw Crushers and How Do They Work? Oreflow

The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down4 天之前 Jaw Crushers Designed to crush ROM feed material for demanding quarrying, mining, and demolition purposes With their unique Elliptical motion of the swing jaw Crushers, ensure highly efficient production rates at any settingJaw Crushers Manufacturer in India Puzzolana2024年8月6日 Blake Jaw Crusher: This type of jaw crusher has a fixed feed area and a variable discharge area It is used to crush materials with compressive strength less than 320 MPa Universal Jaw Crusher: This type of jaw crusher is versatile and can handle a wide range of materials It has a fixed jaw plate and a movable jaw plate that is hinged at the Jaw Crusher for Sale Compare Prices SuppliersFor example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimensionJaw Crusher Explained saVRee